Humidity

is the presence of water in air. The amount of water vapor in air can

affect human comfort as well as many manufacturing processes in

industries. The presence of water vapor also influences various

physical, chemical, and biological processes.  Humidity

measurement in industries is critical because it may affect the

business cost of the product and the health and safety of the personnel.

Hence, humidity sensing is very important, especially in the control systems for industrial processes and human comfort.

Humidity

measurement in industries is critical because it may affect the

business cost of the product and the health and safety of the personnel.

Hence, humidity sensing is very important, especially in the control systems for industrial processes and human comfort.

Controlling

or monitoring humidity is of paramount importance in many industrial

& domestic applications. In semiconductor industry, humidity or

moisture levels needs to be properly controlled & monitored during

wafer processing. In medical applications, humidity control is required

for respiratory equipments, sterilizers, incubators, pharmaceutical

processing, and biological products. Humidity control is also necessary

in chemical gas purification, dryers, ovens, film desiccation, paper and

textile production, and food processing. In agriculture, measurement of

humidity is important for plantation protection (dew prevention), soil

moisture monitoring, etc. For domestic applications, humidity control is

required for living environment in buildings, cooking control for

microwave ovens, etc. In all such applications and many others, humidity sensors are employed to provide an indication of the moisture levels in the environment.

RELEVANT MOISTURE TERMS

To

mention moisture levels, variety of terminologies are used. The study

of water vapour concentration in air as a function of temperature and

pressure falls under the area of psychometrics. Psychometrics deals with

the thermodynamic properties of moist gases while the term “humidity’

simply refers to the presence of water vapour in air or other carrier

gas.

Humidity

measurement determines the amount of water vapor present in a gas that

can be a mixture, such as air, or a pure gas, such as nitrogen or argon.

Various terms used to indicate moisture levels are tabulated in the

table below:

S.No

|

Term

|

Definition

|

Unit

|

1

|

Absolute Humidity

(Vapor Concentration)

|

Ratio of mass(vapour) to volume.

|

|

2

|

Mixing Ratio OR Mass Ratio

|

Ratio of mass(vapour) to mass(dry gas)

|

grams/m3

|

3

|

Relative Humidity

|

Ratio of mass(vapour) to mass(saturated vapour) OR ratio of actual vapor pressure to saturation vapor pressure.

|

%

|

4

|

Specific Humidity

|

Ratio of mass(vapour) to total mass.

|

%

|

5

|

Dew Point

|

Temperature(above 0°C) at which the water vapor in a gas condenses to liquid water)

|

°C

|

6

|

Frost Point

|

Temperature(below 0°C) at which the water vapor in a gas condenses to ice

|

|

7

|

Volume Ratio

|

Ratio of partial pressure(vapour) to partial pressure (dry gas)

|

% by volume

|

8

|

PPM by Volume

|

Ratio of volume(vapour) X 106 to volume(dry gas)

|

|

9

|

PPM by Weight

|

PPMV X

|

PPMW

|

Most

commonly used units for humidity measurement are Relative Humidity

(RH), Dew/Frost point (D/F PT) and Parts Per Million (PPM). RH is a

function of temperature, and thus it is a relative measurement.

Dew/Frost point is a function of the pressure of the gas but is

independent of temperature and is therefore defined as absolute humidity

measurement. PPM is also an absolute measurement.

Dew

points and frost points are often used when the dryness of the gas is

important. Dew point is also used as an indicator of water vapor in high

temperature processes, such as industrial drying.

Mixing

ratios, volume percent, and specific humidity are usually used when

water vapor is either an impurity or a defined component of a process

gas mixture used in manufacturing.

Correlation among RH, Dew/Frost point and PPMv is shown below:

HUMIDITY SENSING – CLASSIFICATION & PRINCIPLES

According

to the measurement units, humidity sensors are divided into two types:

Relative humidity(RH)sensors and absolute humidity(moisture) sensors.

Most humidity sensors are relative humidity sensors and use different sensing principles.

A table showing important parameters of different types of humidity sensors is given below:

Active Material

|

Thermo-set

Polymer

|

Thermoplastic

Polymer

|

Thermoplastic

Polymer

|

Bulk Thermoplastic

|

Bulk

AlO3

|

Lithium

Chloride Film

|

Substrate

|

Ceramic or

Silicon

|

Ceramic or

silicon

|

Polyester or

mylar film

|

N/A

|

N/A

|

Ceramic

|

Sensed Parameter

|

Capacitance

|

Capacitance

|

Capacitance

|

Resistance

|

Resistance

|

Conductivity

|

Measured Parameter

|

%RH

|

%RH

|

%RH

|

%RH

|

%RH

|

%RH

|

RH Change

|

0% to 100%

|

0% to 100%

|

0% to 100%

|

20% to 100%

|

2% to 90%

|

15% to <100%

|

RH Accuracy

|

±1% to ±5%

|

±3% to ±5%

|

±3% to ±5%

|

±3% to ±10%

|

±1% to ±5%

|

±5%

|

Interchangability

|

±2% to

±10% RH

|

±3% to

±20% RH

|

±3% to

±20% RH

|

±5% to

±25% RH

|

poor

|

±3% to

±10% RH

|

Hysterisis

|

<1% to 3% RH

|

2% to 5% RH

|

2% to 5% RH

|

3% to 6% RH

|

<2% RH

|

very poor

|

Linearity

|

±1% RH

|

±1% RH

|

±2% RH

|

poor

|

poor

|

Very poor

|

Risetime

|

15 s to 60 s

|

15 s to 90 s

|

15 s to 90 s

|

2 min to 5 min

|

3 min to 5 min

|

3 min to 5 min

|

Temperature

Range

|

-40 °C to

185 °C

|

-30 °C to

190 °C

|

-25°C to

100 °C

|

10 °C to

40 °C

|

-10 °C to

75 °C

|

-

|

Long Term

Stability

|

±1%RH/5 yr

|

±1%RH/yr

|

±1%RH/yr

|

±3%RH/yr

|

±3% RH/yr

|

>1% RH/°C

|

· Sensing Principle

Humidity

measurement can be done using dry and wet bulb hygrometers, dew point

hygrometers, and electronic hygrometers. There has been a surge in the

demand of electronic hygrometers, often called humidity sensors.

Electronic

type hygrometers or humidity sensors can be broadly divided into two

categories: one employs capacitive sensing principle, while other use

resistive effects

Sensors based on capacitive effect:

Humidity

sensors relying on this principle consists of a hygroscopic dielectric

material sandwiched between a pair of electrodes forming a small

capacitor. Most capacitive sensors use a plastic or polymer as the

dielectric material, with a typical dielectric constant ranging from 2

to 15. In absence of moisture, the dielectric constant of the

hygroscopic dielectric material and the sensor geometry determine the

value of capacitance.

At

normal room temperature, the dielectric constant of water vapor has a

value of about 80, a value much larger than the constant of the sensor

dielectric material. Therefore, absorption of water vapor by the sensor

results in an increase in sensor capacitance.

At

equilibrium conditions, the amount of moisture present in a hygroscopic

material depends on both the ambient temperature and the ambient water

vapor pressure. This is true also for the hygroscopic dielectric

material used on the sensor.

By

definition, relative humidity is a function of both the ambient

temperature and water vapor pressure. Therefore there is a relationship

between relative humidity, the amount of moisture present in the sensor,

and sensor capacitance. This relationship governs the operation of a

capacitive humidity instrument.

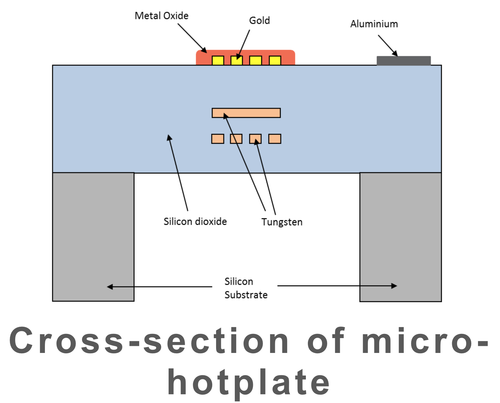

Basic structure of capacitive type humidity sensor is shown below:

On

Alumina substrate, lower electrode is formed using gold, platinum or

other material. A polymer layer such as PVA is deposited on the

electrode. This layers senses humidity. On top of this polymer film,

gold layer is deposited which acts as top electrode. The top electrode also

allows water vapour to pass through it, into the sensing layer . The

vapors enter or leave the hygroscopic sensing layer until the vapour

content is in equilibrium with the ambient air or gas.Thus capacitive type sensor is basically a capacitor with humidity sensitive polymer film as the dielectric.

Sensors based on Resistive effect:

Resistive

type humidity sensors pick up changes in the resistance value of the

sensor element in response to the change in the humidity. Basic

structure of resistive type humidity sensor from TDK is shown below

Thick

film conductor of precious metals like gold, ruthenium oxide is printed

and calcinated in the shape of the comb to form an electrode. Then a

polymeric film is applied on the electrode; the film acts as a humidity

sensing film due to the existence of movable ions. Change in impedance

occurs due to the change in the number of movable ions.