Force sensors are also known as force

transducers that converts an input mechanical force into an electrical output

signal. It act as a force sensing resistor in an electric circuit.

It has various benefits such as flexibility

and ultra-thin sensor construction which leads to minimal interference in

normal action of device and precise response. Depending upon the working and

sensing method, variety of force sensors are available in the market.

Force Sensor Market: Drivers and Restraint

The global force sensor market is expected

to witness substantial growth over the period of forecast. Technological

advancement, low manufacturing cost, increasing product demand, rise in the

demand of industrial robots, advancement of medical devices with force sensing

technology, innovations and development in the manufacturing are the few

factors encouraging the growth of global force sensor market.

On the other hand, factors which are

restraining the global force sensor market are instability in the demand across

various end-user industry and underdeveloped aftermarket sales channels.

Force Sensor Market: Segmentation

The global force sensor market can be

segmented into type, application and region.

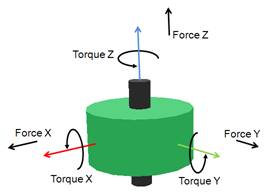

On the basis

of type, the global force sensor market can be segmented into, optical force

sensor, piezoresistive force sensor, capacitive force sensor, magnetic force

sensor, ultrasonic force sensor, strain gauges, and electrochemical force

sensors

Sensors has

become an essential part of any measurement and automation applications.

Overall global sensor market is witnessing a trend of increasing sensor

accuracy, reliability, response time, efficiency, communication capability and

robustness encourages the demand for sensors across various applications.

On the basis

of application, the global force sensor market can be segmented into, medical

& pharmaceutical sector, automotive, printing & packaging, consumer

electronics, industrial (robotic & manufacturing), and aerospace &

defence. Key developments in the prominent industries such as medical &

pharmaceuticals, robotics, aerospace & defence, manufacturing and others is

expected to encourage the growth of global force sensor market by 2025.

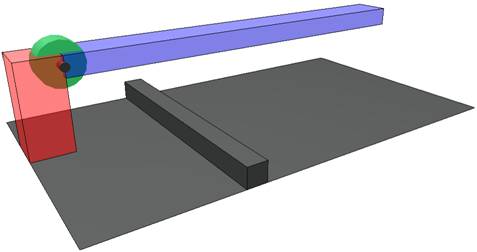

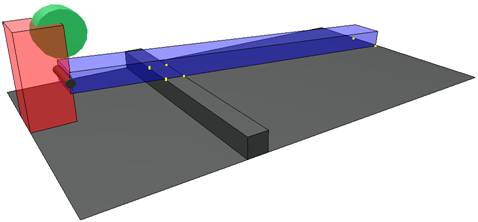

Force sensors

are used in manufacturing tools, transportation equipment, microelectronic

packaging, transportation equipment. Force sensors can also be used in wireless

inventory management system to improve order scheduling which helps in avoiding

inventory stock-out issue.

Force

Sensor Market: Region wise outlook

On the basis

of region, the global force sensor market can be seven regions which include –

North America, Latin America, Asia-Pacific excluding Japan (APEJ), Western

Europe, Eastern Europe, Japan and Middle East & Africa. North

America is dominating the global force sensor market due to high

technological advancement and increasing adoption among various end-user

applications.

However,

revenue contribution from Asia Pacific excluding Japan

Force Sensor Market: Key Players

Key players in the global force sensor

market are FUTEK Advanced Sensor Technology, Inc., OMRON Corporation, Texas

Instruments Incorporated are the top players are global force sensor market.

Apart from them, various other players are existing in market such as TE

Connectivity Ltd., Tekscan, Inc., ATI Industrial Automation, and Sensata

Technologies, Inc.

Key players are focusing on development of

new technologies and new product launch. Merger and acquisition is another activity

observed in the market by the market participants to increase their product

portfolio and to grow the business.

The growth in global force sensor market is

also due to growing awareness about the potential use of force sensors in

different electronic devices by the original equipment manufacturers. For

example, in August 2015, Apple, Inc.

posted a patent report, “An Advanced Force

Touch Patent for the iPad Surfaces in Europe ”

to develop techniques to integrate the force sensors into the iPhone and iPad.