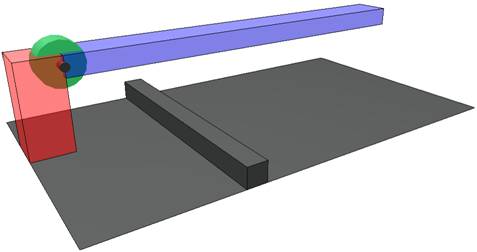

Force sensors are initially rigid links between two shapes that are able to measure transmitted forces and torques. The rigidity of force sensors is conditional, in the sense that force sensors can be broken if a certain condition arises (e.g. if a force or torque threshold is overshot). Following figure illustrates an application using a force sensor:

[Force sensor object (green) measuring the force and torque exerted by a beam (blue) anchored in a wall (red)]

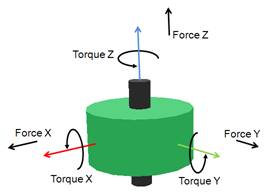

A force sensor measures a pair of 3 values representing the force on the sensor along the x-, y- and z-axis, and the torque on the sensor about the x-, y- and z-axis:

[Forces and torques measured by a force sensor]

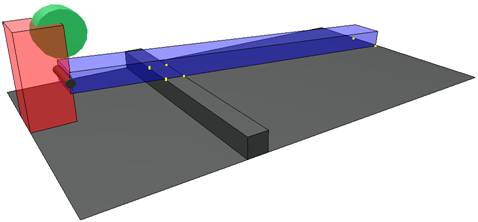

[Broken force sensor]

A force sensor is only operational during simulation if it is dynamically enabled. For more information on dynamically enabled force sensors, refer also to the section on designing dynamic simulations. Joints are also able to measure a force or a torque, however only along/about their z-axis.

This is really nice blog. i feel happy to read this CO2 Gas Transmitter blog information.Thanks for sharing this information with us. Acorn Controls Pvt.Ltd. is also one of the best company that manufacturer and supply the Ultrasonic Flow Meter.

回复删除